Thermocouple Extension Cables

Thermocouples are used to measure temperature in various applications. Pairs of conductors made of dissimilar alloys are joined together at an exposed end, which is exposed to a heat source. This generates a small change in the resitance of the material and a subsequent voltage change when a current is applied, typically measured in micro-Volts; this is known as the "Seebeck Effect." This voltage change has a non-linear relationship to the temperature of the source and it is converted into from Volts to ºC or ºF to determine the temperature at the junction.

While Dekoron does not manufacture thermocouples themselves, however, we do offer some of the highest quality thermocouple extension cables available on the market today. These extension cables are used to connect remote thermocouples to a central control and/or monitoring facility, and are designed to provide superior performance even over long cable runs.

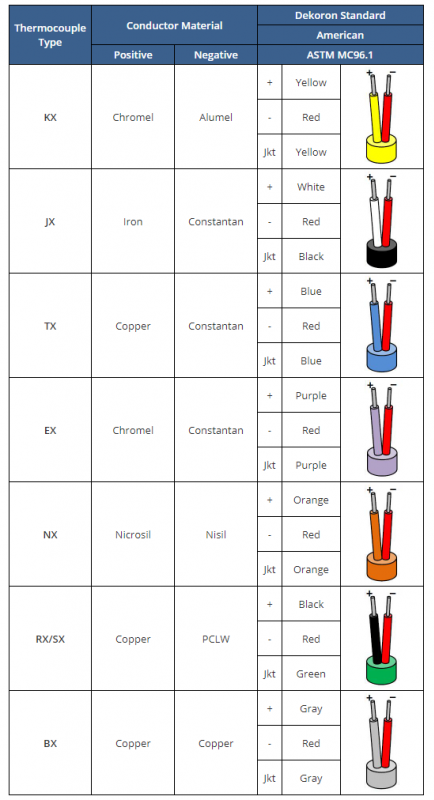

Thermocouple Types & Colors

There are several different alloy combinations that are available, and there are numerous standards which dictate various identification methods for said combinations. Dekoron's standard themocouple extension cables are built to the ASTM MC96.1 standard.

Please note that there are many other color codes and standards that Dekoron can manufacture thermocouple cables to. Please take a look at the Thermocouple Conductor & Color Code Page if you would like to know more about the additional choices available.

Construction Options

Conductor

- Types KX, JX, EX, TX, SX, and RX, in solid, 7-strand, or 19-strand configurations from 20 AWG to 14 AWG and equivalent metric sizes.

Insulation

- PVC, XLPE, HDPE, or PVC/Nylon.

Shielding

- Dekoron provides a variety of options for shielding to prevent EMI (electro-magnetic interference) within the twisted pairs and for the overall cable using our patented application process.

- Aluminum or copper tapes with a polyester backing for individual and overall shields, used with drain wires. Drain wires are placed in direct contact with the shield to facilitate grounding and easy termination

- Bare or Tin-Coated Copper Braid is also available.

Armor

- Served Wire Armor (SWA), Galvanized Steel or Aluminum.

- Interlocked Armor, Galvanized Steel or Aluminum

- Gardex® Corrugated, Continuously-Welded Aluminum.

- Dekabon® Chemical & Moisture Barrier

- Stainless Steel Braid

Jacket (Sheath)

- PVC, HDPE, CPE, or TPN (LSZH).

Cable Markings

- All cables are printed with required voltage and temperature rating, as well as applicable regulatory approvals.

- All cables have traceability and sequential length markings.

Packaging & Documentation

- Depending on the size of the cable, the products are delivered on wooden reels up to 96” in diameter.

- There is an option to lag wood reels using wooden planks that are secured to the outer edges of the reel to prevent damage to the cable while in transit. The wooden reels are heat-treated to comply with international phytosanitary requirements. Overseas shipments are crated. We also offer light-weight fiber board reels for air freight shipments.

- The ends of the cables, known as the “pig tails,” are exposed on the reels for any testing at the receiving location, but sealed for shipment.

- If requested Dekoron can provide Certificates of Conformance at the time of shipment.

Approvals & Ratings

Dekoron can offer a variety of ratings and standards for instrumentation products. Please discuss the specific rating and approvals with your customer service representative prior to placing your order. Depending on the cable design and selection of armor types, the following approvals are available:

Design Standards

- UL 13 (PLTC & PLTC-ER), UL 2225 (ITC-HL), UL 2250 (ITC & ITC-ER), ICEA S-73-532, BS 5308, EN 50288-7, AS/NZS 5000

Flame Retardancy Standards

- IEEE 1202, UL 1685, VW-1, FT4, IEC 60332

Temperature Rating

- -50ºC to 105°C, typical. Up to 260°C with fluoropolymers.

Hazardous Zone Classifications

- Class I, Division 2, and Class I, Zone 2 & 3 Ratings are Available.

Other Options & Standards

- Low Smoke Zero Halogen, per IEC 61034 and IEC 60754

- Conductors per ASTM B3, B33, B8, and IEC 60228, AS/NZS 1125

- REACH & RoHS Compliant.

- ER (Exposed Run) rating is available for many constructions. ER rated cables are designed and tested for impact and crush resistance per UL criteria. With the ER rating, cables are allowed to run outside of trays or conduit for an unlimited distance, provided the cable is supported every 6 feet or less.

Gardex® is a registered trademark of Marmon Specialty Cable

Dekabon® is a registered trademark of Dekoron Wire & Cable